deburring Blusher

Compact Auto Efficient Deburring Machine

No need hand work

deburring Blusher

Deburring is a very important process in manufacturing.

For that reason, there are not a few companies that spend a lot of time and cost on deburring work

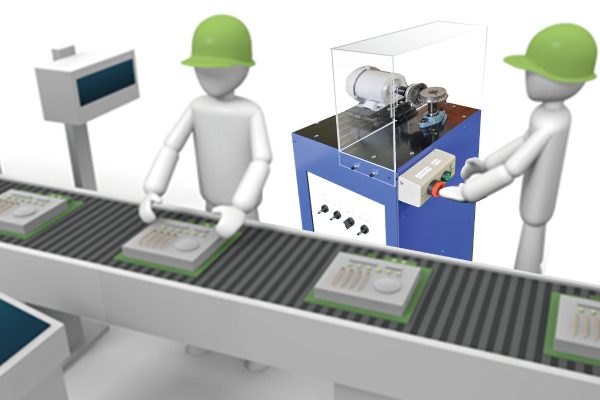

We will introduce an automatic deburring machine \”Blusher\” which is conpact and can move easyly.

You need helps?

- The machine can not be placed near the production line and it is inefficient.

- It takes too much time and cost for hand deburring work

- There is no optimum machine for the parts, etc.

deburring Blusher

No need hand work

Very compact!

Easy to move

easy to customize

Customize according to your request

deburring Blusher

5 merits

-

Easy to Improve

Improve efficiency more than hand deburring

-

Easy to Move

It’s on casters Easy to move

-

Easy to Install

Installation near the production line and can do deburring work.

-

Easy to Customize

Customize according to your request.

-

very Compact

it’s compact design. W400xD520

| Subject | Specification contents |

|---|---|

| Power supply | AC200V 50Hz・60Hz |

| Dimension of target workpiece | φ150 H50 Weight: 1.5 kg or less |

| Work rotation speed | 1.2-18.6RPM(Speed change possible at 50Hz) |

| Brush rotation speed | 1410RPM(Fixed at 50Hz) |

| Brush wear correction | Work adjuster(By handle) |

| Processing | Dry type |

| Body weight | 90Kg |

Specification of deburring Blusher

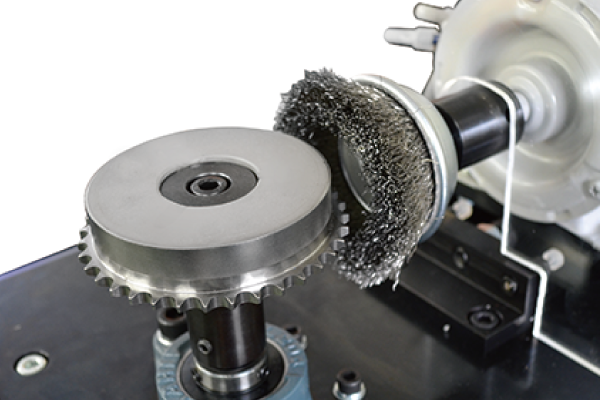

2 way brush

Common specification

The direction of rotation of the work, you can choose either clockwise or counterclockwise.

*You can also install a rotation changeover switch.(option)

With the handle, you can adjust the pressing of the brush.

*It is also possible to use an air cylinder.(option)

(Thrust is adjusted with a pressure reducing valve.)

The rotation speed of the work can be adjusted with the knob.

Jigs for work set are not included, so please prepare.

*We also accept designing and manufacturing jigs.

*By moving the brush, it can also take burrs in several places.(option)

Brush on the side System

Brush the upper surface System

Many other benefits

It can be installed easily on the production line. The installation space is for one person.

Various options!

◆ Movable section automatic door(Danger prevention)

◆ Full cover(metallic)

◆ Work rotation axis orientation function

◆ Work presence / absence sensor

◆ External input / output function(Relay terminal box)

◆ Status indicator light

◆ Work counter stopping function

◆ Brush wear notification function

◆ Operation touch panel(4 inch monitor)

Contact Us

Do you have other questions about Blusher?

Just fill out the form below and we’ll get back to you as soon as possible

(usually within three business days).

Depending on your usage environment, as well as spam mail prevention measures etc, your reply may not arrive.

Please make it possible to receive mail from “@ogisei.com”